Zirconium Silicate (ZrSiO₄) is a naturally occurring mineral that is commonly processed to produce a fine, white powder known for its high stability and resistance to high temperatures. It is primarily composed of zirconium, silicon, and oxygen and is often used in various industrial applications due to its excellent properties. Zirconium silicate is particularly valued in ceramics, glass, and refractory materials for its durability, low thermal expansion, and ability to enhance the mechanical strength of products.

Zirconium silicate, in pottery, often referred to as Zircopax, is widely used as an opacifier in glazes and clay bodies to achieve a smooth, matte finish and enhance the whiteness of ceramic products. Its excellent stability at high temperatures makes it ideal for use in a variety of firing conditions, helping to prevent issues such as crazing or cracking. Zircopax contributes to improved mechanical strength and durability of ceramics, ensuring that finished pieces can withstand everyday use. Additionally, its ability to effectively scatter light results in vibrant colors and a uniform appearance, making it a valuable additive for potters seeking to create high-quality, aesthetically pleasing ceramic ware.

Appearance:

-A fine, white powder

-Generally odorless and non-toxic.

Other applications in different industries:

1. Glass Manufacturing:

Incorporated into glass formulations to improve strength and reduce thermal expansion.

2. Refractories:

Serves as a key ingredient in high-temperature refractory materials, providing stability and resistance to wear and thermal shock.

3. Paints and Coatings:

Acts as a pigment and filler in paints, improving opacity and providing a white finish.

4. Dental Ceramics:

Utilized in dental materials for its strength and aesthetic qualities, contributing to the durability and natural appearance of dental restorations.

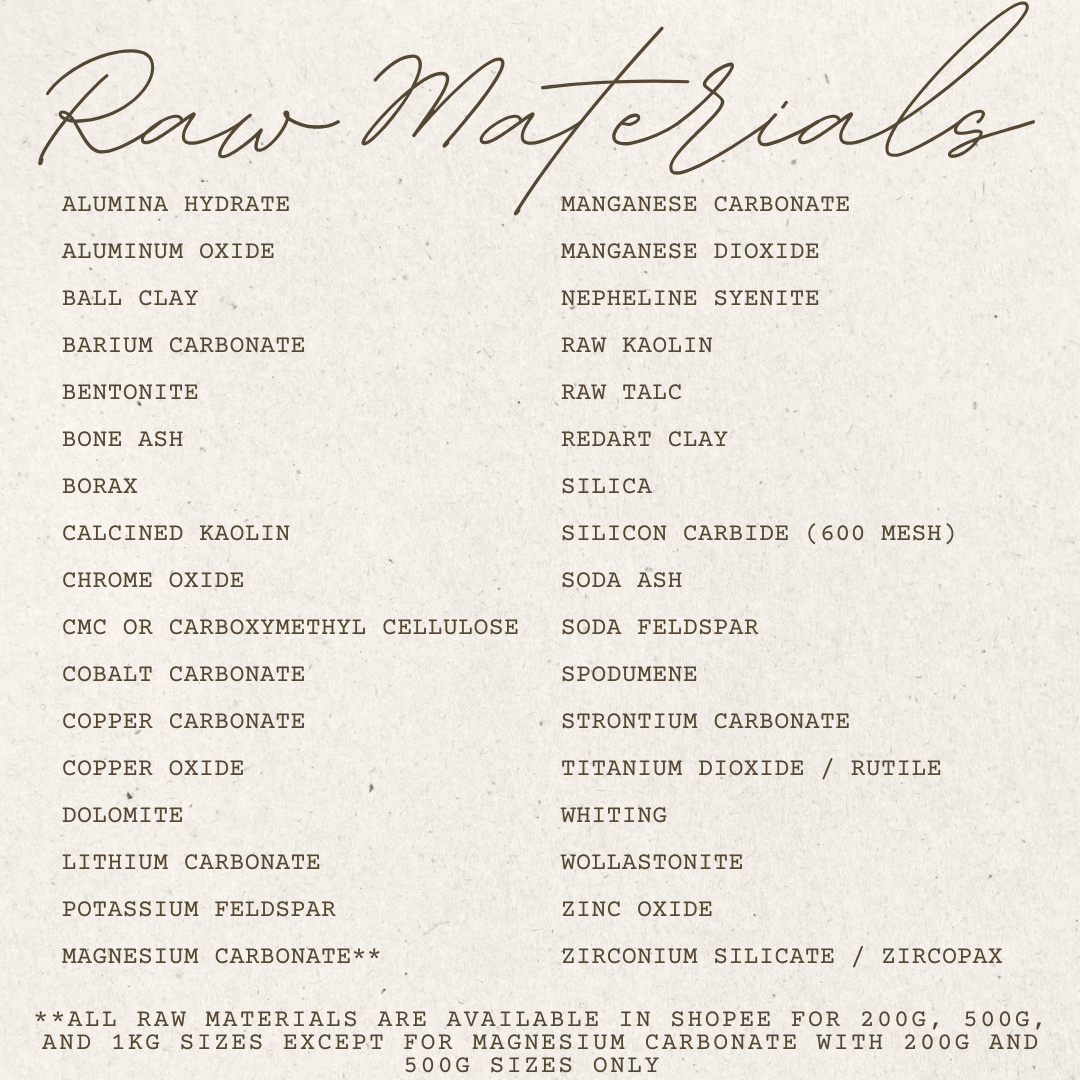

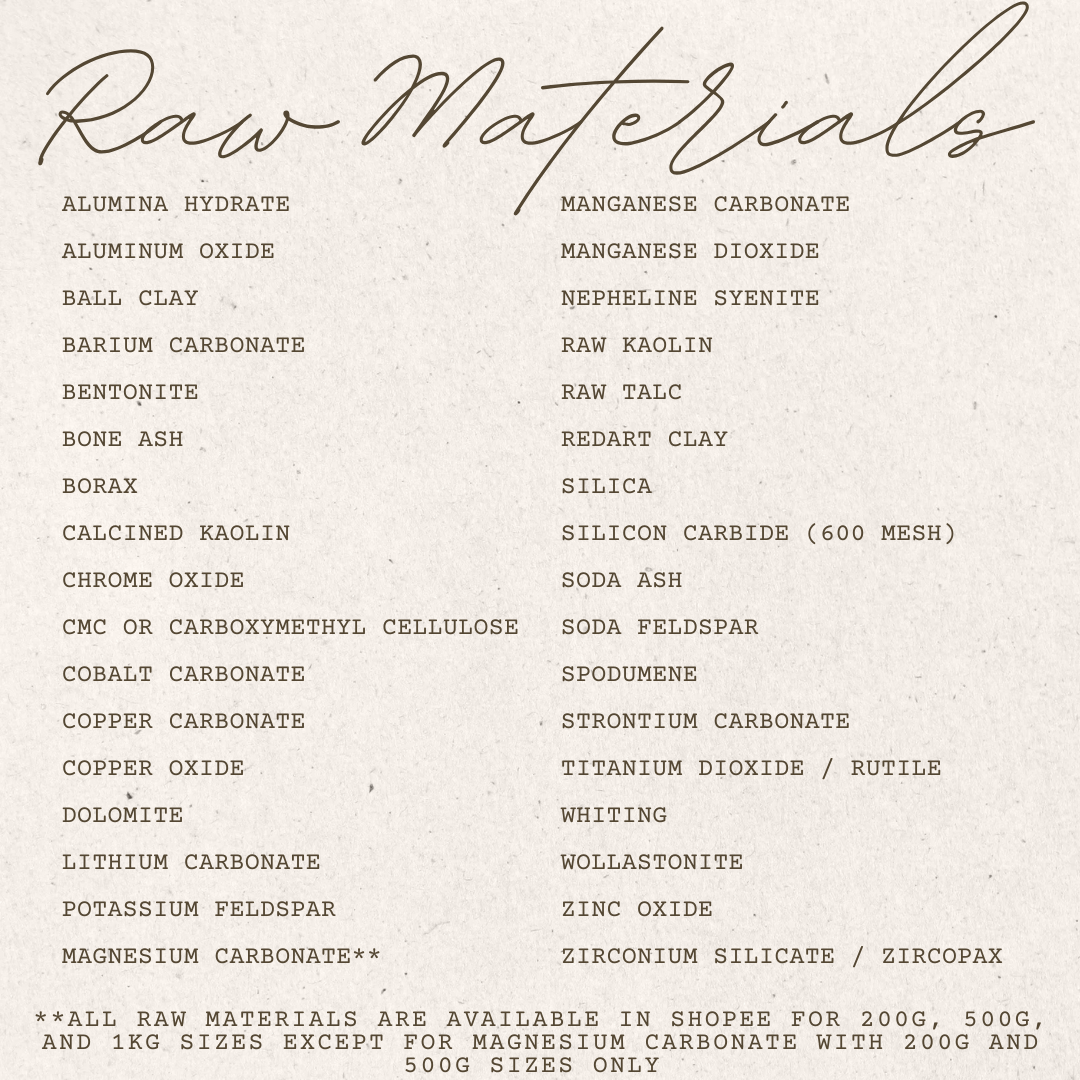

NOTE: All Raw Materials are very fine-grained (200-325 Mesh).