Potassium Feldspar, also known as K-feldspar or orthoclase, with its unique fluxing properties, combined with its stability and alkali content, make it a vital material in ceramics, glass, and other industries. It plays a crucial role in achieving high-quality, durable, and aesthetically pleasing finished products.

Potassium Feldspar, in pottery, is a crucial fluxing agent used in both clay bodies and glazes. It helps lower the melting point of the materials, promoting vitrification and creating smooth, glassy surfaces on finished ceramic pieces. The presence of potassium in feldspar enhances the strength and durability of the fired product while contributing to a range of glaze effects, including improved gloss and color development. Its role in mid- to high-temperature firings ensures that ceramics are more resistant to wear and thermal shock, making potassium feldspar essential for creating functional and decorative pottery with high-quality finishes.

Appearance:

-White powder

Other applications in different industries:

1. Glass Manufacturing:

A key ingredient in the production of glass, where it helps improve the workability, clarity, and strength of the glass.

2. Construction:

Employed in the production of tiles, sanitary ware, and other construction materials where its fluxing properties aid in creating dense, durable products.

3. Abrasives:

Used in the production of abrasives for polishing and grinding due to its hardness and stability.

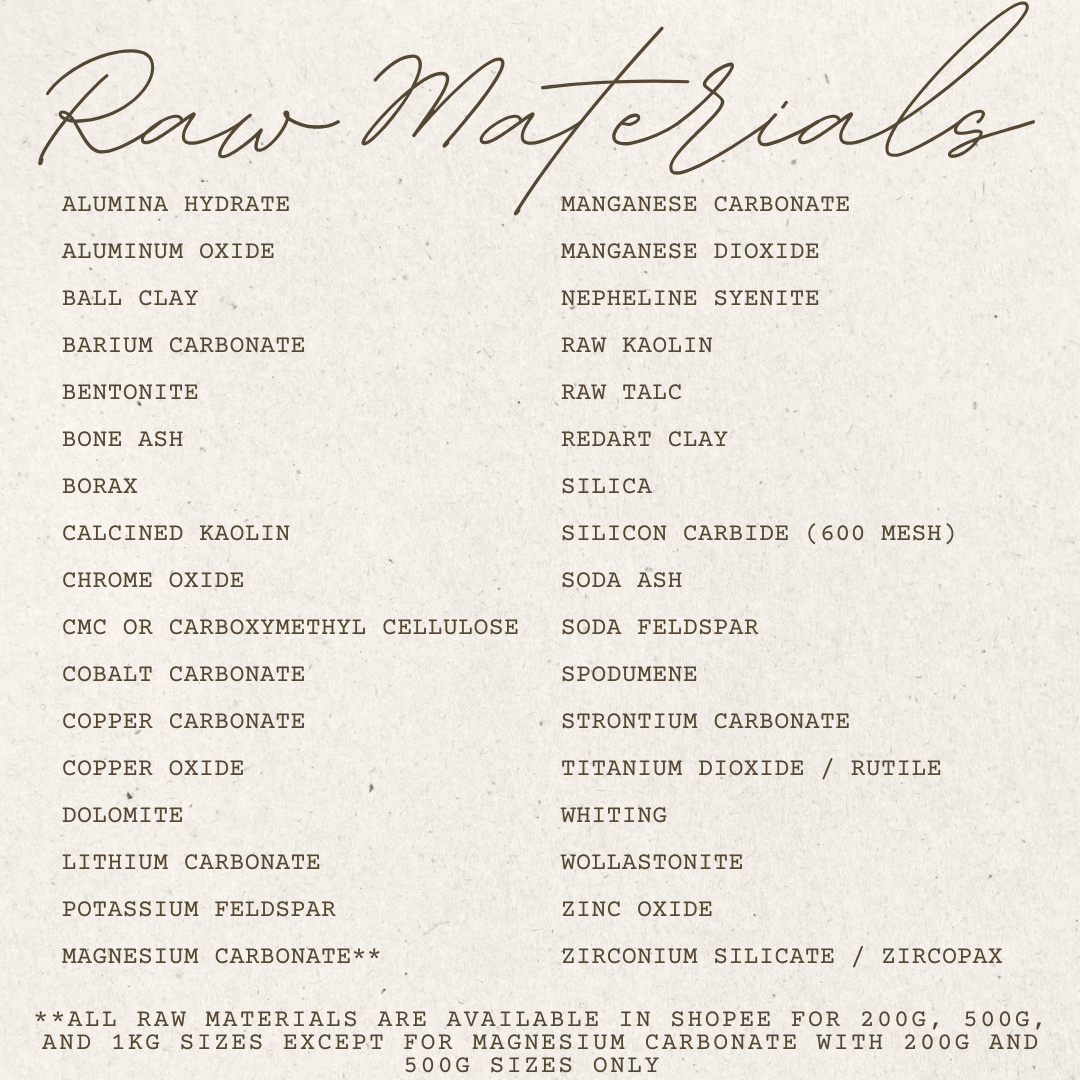

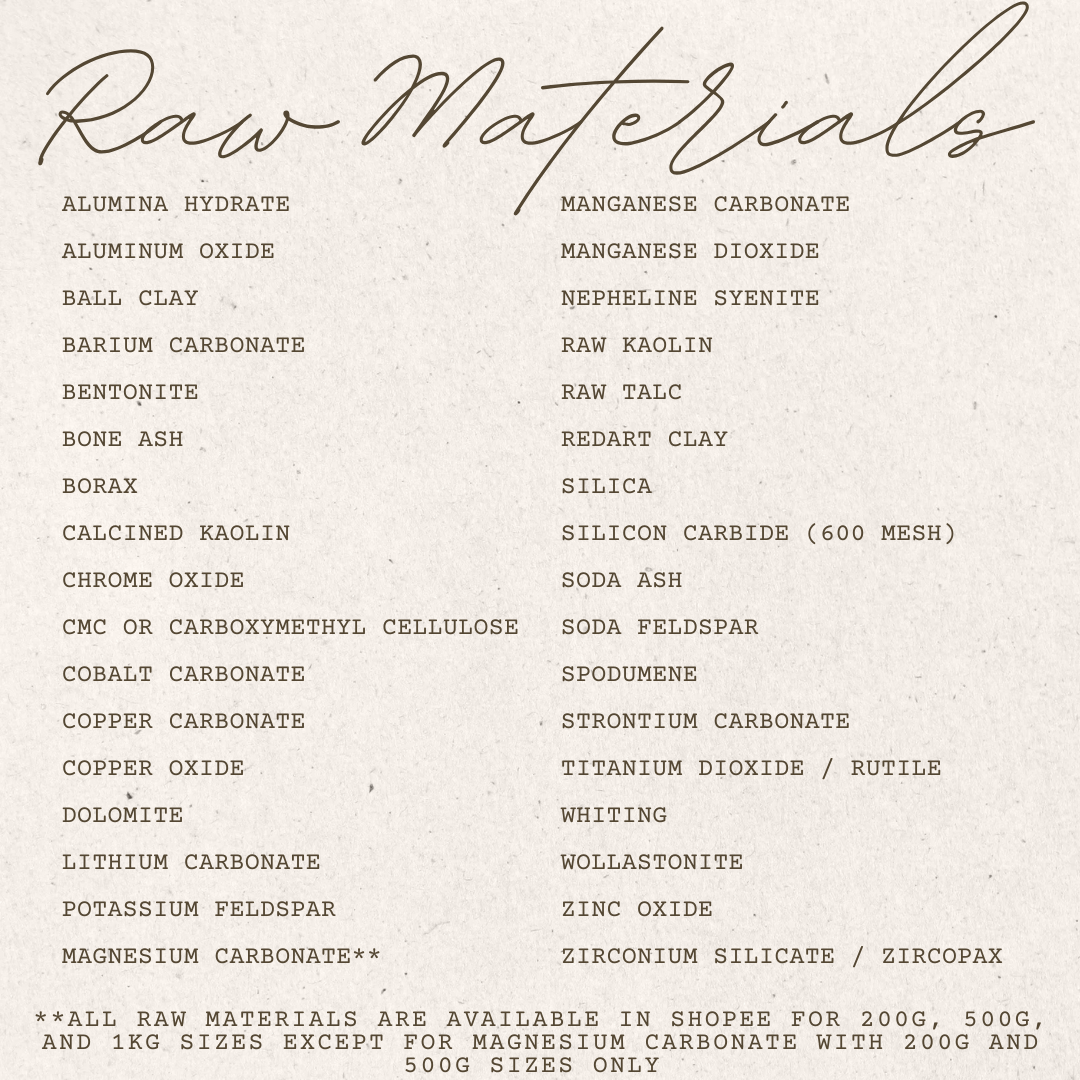

NOTE: All Raw Materials are very fine-grained (200-325 Mesh).